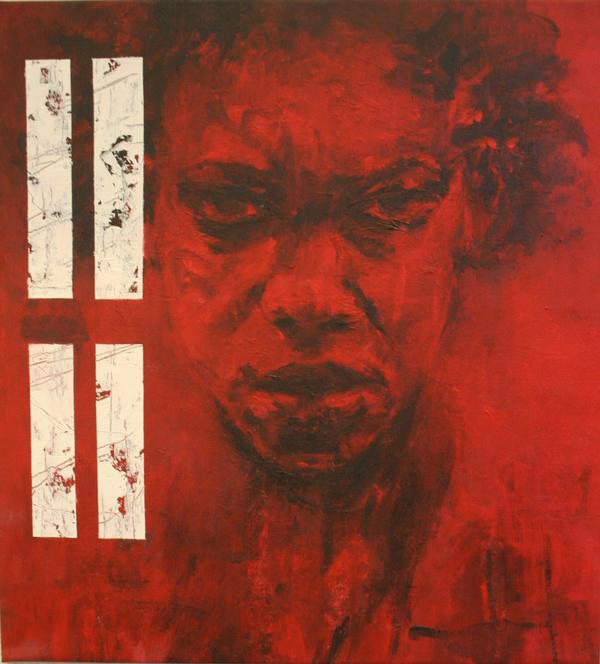

We are pleased to share the digital projection that was shown at the African Burial Ground during the month of December and early January. The artist, Patrick Singh created these works while he was in New York, France and Burkina Faso.

Tag: African culture

African metalworks

Background to metalworking in Africa

There is enormous variety in African metalworking, in terms of the metals used, the techniques employed, and the objects produced.

Historically, the metals used most in Sub-Saharan Africa were iron, copper, bronze (alloy of copper and tin), brass (alloy of copper and zinc), and gold. There was also some localized use of lead, tin, silver, and more recently, aluminium.

There are substantial gold deposits in Africa, as well as a range of iron ores. Copper is sparse in west Africa, but is plentiful in parts of southern and central Africa.

History

In ancient Egypt, metal was smelted from the time of the Old Kingdom (2686–2181 BC). In Sub-Saharan Africa, it is not known precisely when native metals were first worked, but in parts of Niger and Mauritania, copper was smelted from the early first millennium BC. By AD 1000 metal use was almost universal in Africa. The ‘Three Age System’ of stone-use, followed first by bronze, and then by iron, does not apply to the history of metals in Africa. Almost everywhere, iron, copper, bronze, and brass were introduced at virtually the same time.

Techniques

-

Smelting

involves extracting a metal from its ore (a mineral containing the metal) by heating the metal ore in a furnace to a very high temperature. During the smelting process, oxygen in the ore combines with carbon in the fuel, escaping as carbon monoxide or carbon dioxide, leaving the metal in liquid form. Other impurities are also removed during the smelting process. During smelting, the temperature in the furnace is raised and maintained using bellows.

-

Forging metal

is a method of shaping metal by hammering. Cold forging is generally limited to relatively soft metals including gold, silver, and copper alloys. Most metals are hot forged. A metal object produced by hot forging tends to be stronger and less brittle than metal cast in a mould. In addition to hammering, the metal is also shaped by chisels, and by punching tools.

This heavy brass torque from Tanzania was shaped by hammering. The incised patterning was then produced using a sharp tool. It is thought to have been excavated from a Pare grave in the mid-twentieth century, and to have been made some time before 1892. It probably belonged to a woman. Amongst the Pare in the precolonial period, torques like these were made by members of the metalworking clan. They were usually purchased by a girl’s parents and given to her to mark her adulthood and the fact that she was ready to

marry.

-

Lost Wax Casting

An alternative method of shaping metal is by lost wax casting, or cire perdue. This method was used to produce some of the most famous African metalworks, including the Benin brasses (or ‘bronzes’), and Asante weights. It is not known exactly how lost wax casting was developed or introduced to Africa, but it was being practised by West African brass sculptors for several centuries before the arrival of the first Portuguese explorers in the late fifteenth century. Lost wax casting allows hollow metal objects to be produced. A clay or plaster model is made of the desired object. This clay mould is then covered with a layer of wax (or a similar material with a low melting point). The thickness of the wax layer is important, as it determines the eventual thickness of the metal. A second layer of clay is then formed over the wax. Ducts are left in the clay for drainage. The entire mould is then heated so that the wax melts and drains away through the ducts. Molten metal is then poured into the resulting cavity. Once the metal has cooled and hardened, the clay is chipped off, leaving the metal object.

-

Direct Cast Method

This is another method used to shape metal. It produces a metal model of small, organic objects such as seeds or insects. The seed or insect is covered in a thick layer of clay. The clay is then heated so that the organic material is burned away. Molten metal is poured into the cavity through specially prepared ducts. Once cold, the clay cast is then broken off revealing the metal object which is then filed and polished.

Compiled by:

Bryony Reid, Senior Project Assistant (Interpretation)

DCF What’s Upstairs?

October 2005

For more information — please read Kola Adekola’s research paper